Although the forecast is for a cold winter this year, our vivaNext Highway 7 construction schedule calls for us to keep going at full-speed, even while it’s snowy out there. Here’s an overview of what we’re going to be working on this winter along Highway 7, and how we’ll manage to keep going when the temperatures drop.

There’s no doubt that some work – like paving – is best done when it’s warm. So the first rule of project management is to plan the work schedule many months in advance, so work can progress without interruption through all seasons. That means we do the work that has to be done when it’s warmer – such as paving or landscaping – when it’s warm, and use the winter for tasks that can be done at any time of the year.

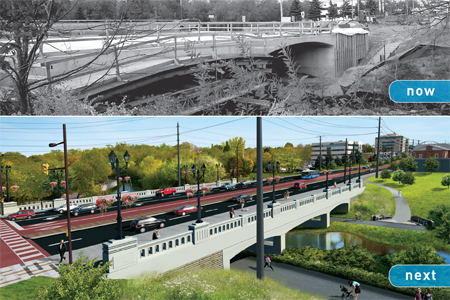

This winter, our focus will be on continuing with the stations along Highway 7 and on the towers connecting Bayview to Highway 7, leaving the road work and landscaping for next spring.

At the Bayview towers our goal is to enclose the south tower before Christmas, including getting the roof on and the glass installed. Once the space is enclosed but not heated, we’ll do some interior work including elevators and electrical work. And when the towers have permanent power, we can warm up the interior using temporary industrial space heaters. Then we’ll start to install tiling and hand railings, both of which use grout which requires warmer temperatures.

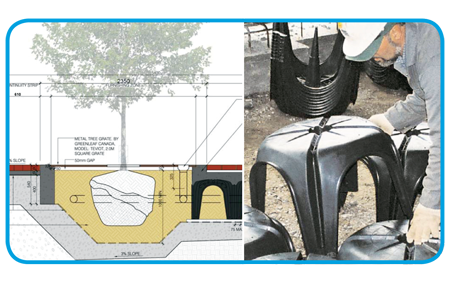

For the stations along Highway 7, working in the winter requires some additional measures which allow us to keep going. One design advantage we have is that our station platform foundations are built with concrete piers sunk into the ground, rather than a compacted granular base which would be a challenge in the winter. We’ll be able to dig the holes for the piers throughout the winter by heating the subsurface before pouring concrete. After the pour, the concrete is covered with insulated blankets and heated with diesel-fired “frost-fighter” heaters. These heaters – about five times as powerful as a typical home furnace – provide enough heat to help concrete cure, even when it’s cold. And when we know it’s going to snow, the entire platform is covered with tarps to keep the snow off our work site.

So with a lot of advance planning, we’ll be able to continue pouring the foundations and platforms throughout the winter. Come next spring we can get back to the road work and landscaping, with our goal unchanged of having the first section of the Highway 7 rapidway operational in 2013.

[poll id=”37″]